Steam boiler on the ships

Steam boiler

Steam boiler is a closed vessel that can form steam with a pressure greater than 1 atmosphere, by heating the boiler water in it with hot gases from burning fuel.

Steam Power Plant : D nature of installations tanaga steam, absolutely must be equipped with the Boilers and there should be the aircraft that use steam. On ships using fresh water must be saved, the used steam from the steam planes must be attempted to be condensed again in the condenser so that the condensate water can be used again in the boiler.

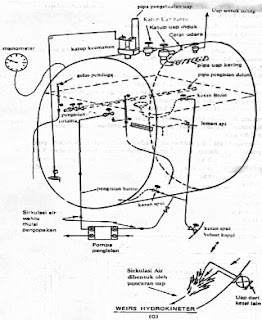

The rotation of the turbine is too high, it is not possible to be used to directly rotate the propeller then it must be lowered first through the reduction gear H then forwarded to the propeller K through the thrust bearing I and the shaft between J.The picture above shows that A is a boiler kitchen, where fuel is burned by the E (brander) incinerator. The result of combustion is obtained by heat which is used to heat the water inside the pipes C. The resulting steam is collected in the B steam drum, then flowed to the heater D (superheater) in order to obtain further hot / dry steam which is then used to drive the Turbine G.

Used steam from the turbine cannot be discharged directly into the atmosphere because the used steam can be used again by condensing (condensed) into water in the condenser M. The condensate water that is produced is then sucked by the condensate pump O to be channeled to the reservoir, which is a hot tub (hotwell) ) P. The filling water from the hot tub P is then sucked up by the filling pump Q which will be forwarded to the kettle via the preheater R and economiser F.

Circulation pump L is used to suck seawater as a cooling medium in the condenser and then discharged back into the sea.

The ejector / air pump N is useful for making the pressure in the condenser smaller than the atmospheric pressure (vacuum), so that the opposing pressure from used vapor is reduced.

A steam boiler must meet the following requirements :

1. In a certain time must be able to produce steam with a certain weight and pressure greater than 1 atmosphere. 2. The resulting steam must be with a water content as little as possible 3. If further heating is used, then in irregular use of steam, the temperature of the steam should not change much and must be easily regulated 4. At the time of motion where the use of steam changes -rubah then takanan steam should not change much 5 .Uap should be formed with the amount of fuel as low as possible 6 .Susunan pengopakan fuel must be such that the fuel can be burned by not requiring the cost and effort is too great.

DISTRIBUTION OF Steam Kettles A. Division According to the Steam Law. Because the places of use vary, according to the Steam Act article 9, the Steam Boiler is divided into three namely: 1. Fixed Boilers or Land Boilers, namely boilers that are used on land such as factories, power plants and others that have a fixed foundation. 2. Boiler Boats, namely boilers used on ships. Here the equipment for the safety of the boilers usually has a slightly different construction from the other boilers, bearing in mind the condition of ships which are always shaking during sailing. 3. Kettle that can move. that is, the boilers which are not included in the two categories of boilers mentioned above, such as train boilers, boiler stakes and others. B. Division According to its construction Kettle is made to produce steam by heating the water inside it by the hot gas from burning fuel. The kettle must work as efficiently as possible; meaning that it must be able to produce as much steam as possible with the use of minimal fuel. Therefore the boiler construction must be such that the heat from the fuel must be absorbed as much as possible by the boiler water to produce steam. To achieve this, the construction of the boiler is made from the arrangement of pipes that separate water and hot gases that heat the water. Seen from the position of the boiler pipe is divided into: 1.Horizontal Example: B&W Section 2. Vertical example: Foster Wheeler 3. Leaning contoh :B & W Integral Judging from the substances flowing in the pipe, the kettle is divided into three groups, namely: 1. Fire Pipe Adjustment. In this boiler hot gases flow in the pipe, while the heated water is outside the pipe. For example: Kettle Schots, Kettle Cochran

2. Water Pipe Kettle.

In this boiler that flows in the pipe is boiler water, while the heating gas is outside the pipe. At present, the development of water pipe boilers is more rapid.

For example: Kettle Babcock and Wilcox

✔️Foster Wheeler Settings

✔️Yarrow settings

✔️I S D

✔️ESD (ESD I, II, III and IV)

3. Combined Fire Pipes and Water Pipes.

In this boiler there are two types of pipes, namely fire pipes and water pipes. Its construction is generally like Kettle Schots. And it seems that the making of this kettle is to correct the deficiencies found in the Kettle Schots, such as poor circulation of water in the kettle.

For example: Kettle Werkspoor, Kettle Howden - Johnson

C. Division According to Function

On motorboats the use of steam is of course only for auxiliary aircraft. Whereas for steamships, the main use of steam is to drive main engines, while other uses are for the supply of auxiliary aircraft. Therefore according to its function on the ship, the kettle is divided into two groups namely:

1. Mains type of boiler water tubes

That is a boiler that produces steam which is used to drive the main engine. At present the boilers that are used as main boiler are generally water pipe boilers, such as:

✔️Foster Wheeler

▶️I S D ( Internal Superheat D – type)

▶️E S D ( External Superheat D – type)

▶️D S D ( Double Superheat D – type )

▶️ESRD(External Superheat Radiant D-type)

✔️Babcock and Wilcok

➡️B & W Section

➡️B & W Integral

➡️Marine Radiant

✔️Combustion Engineering CEV (Combustion Engineering V-seri) CELTG(Combustion Engineering Law Temp Gas) CELTGR(Comb Eng Law Temp Gas Reheat) Kawasaki Superheat Content Kawasaki Full Cooled Kawasaki Enclosed Membrant.

2. Assist Settings.

Namely a boiler that produces steam, which is used for auxiliary aircraft, such as pumps, heaters and others. The types of boiler that are usually used as auxiliary boilers, for example:

- La Mont Exh Gas Economicer

- Cochran Composite Boiler

- B & W M – type

- Foster Wheeler D – type.

KETEL - KETEL BANTU:

On large motorboats in general have a kettle. The benefits of this auxiliary boiler are for heating on ships, such as space heating, kitchens, fuel. and to move auxiliary aircraft.

Kettles of this kind in general in addition to the lid with fuel oil. usually also combined with utilizing the heat from the exhaust gases coming out of the motor

There are several types of systems or systems, including:

1. On a ship there is an auxiliary kettle oiled with oil. and a separate kettle with a special exhaust gas for the main motor exhaust. And each of them can form its own steam formation.

2. La Mont System.

The La Mont boiler is widely used to utilize a portion of the exhaust gas heat from the main motor for the formation of steam. This boiler is usually placed on the exhaust gas road from the main motor or in the chimney, thus it is higher than the main motor (See picture).

The function of this boiler is actually only as a place for the circulation of heat, while the place of formation of the steam is in another boiler Thus a circulation pump is needed to drain the water inside the auxiliary boiler (eg Cochran) to the La Mont boiler to finally return to the auxiliary boiler after taking heat. The formation of steam produced by the auxiliary kettle is usually at a pressure of about 7 or the water temperature of the boiler about 170 ° C.

The temperature of the flue gas ranges from 300 - 400 ° C and leaves the La Mont boiler approximately 220 ° C.

The La Mont kettle, which is heated by flue gas, is almost entirely a number of spiral pipes. Each spiral pipe is connected to the intake and exhaust cabinet.

A = Hot tub

B = Boiler water filling pump.

C = Save

D = Boiler water circulation pump (La Mont pump).

E = Spiral pipes that function as ktel water heaters

F, G, H = Cover taps.

At the Harbor: Tap H is open. faucet F and G close.

Pump B road. D stop pump.

At Sea: Tap H closes, tap F and G open.

Pumps B and D both run.

Picture: Kettle Assist the La Mont system.

To regulate the boiler pressure is usually done by adjusting the amount of circulating water flow or by regulating the amount of exhaust gas flow through the La Mont boiler.

3. In a boiler there are 2 types of bagging: that is, using oil in the ship at the port, and using the exhaust gas and the main motor when the ship is sailing (See garnbar).

Boilers of this type that are widely used on ships include:

a. COCHRAN SET

b. CLARKSON SET

The construction and method of working of this boiler will be outlined below.

a. Cochran Tunes:

This kettle is a vertical type with a half circle shaped kiln, connected around it by a curved ring to the bottom plates. Combustion products from the combustion chamber through a rounded passageway flow into the fire cabinet and then through the fire pipes into the smoke cabinet at the front of the boiler until finally to the chimney (see Figure). Surrounding the wall plate in a fire cabinet are coated with fire-resistant stones. This is necessary so that the boiler body plate does not get excessive heating.

The top of the kettle as well as the kitchen fire is also in the form of a half circle and for this reason no more support is needed.

For kettle covered with oil, it is important to consider the installation of fire-resistant stones around the kitchen. This is to avoid direct fire on the bottom of the kitchen and the ring of the arch. because this section is a narrow water chamber at the bottom of the boiler where it is a place of deposition of sewage, which can cause serious damage as a result of overheating.

Clarkson Tunes:

This boiler makes it possible to make steam caused by sudden boiling in the conical horizontal finger pipes and run upwards, which are heated on the outside and without any circulation of water in the pipes.

It should be noted that this boiler consists of a leather plate on the outside which encloses a cylindrical combustion chamber inside where finger pipes are placed. The combustion chamber is connected to the lower skin through a curved ring and by removal at the top through a crown-shaped cup.

Movable separator plates connected to the room of pipes placed at the top are used to control the passage of gas around the pipe.

It is a must, that this boiler will work for a long time without being cleaned inside and that this type of pipe installation is only one end, while oil impurities, if any, can burn on the outside if the kettle is dry, without the consequences harmful.

APPENDATION OF Steam Kettle

A.TINJAUAN GENERAL:

Steam Boilers are equipped with a number of equipment including measuring gases, filling valves, manometers, taps, safety valves, etc. that cause the kettle to work. Such tools are called kettle appendations. A definition of kettle appendation is actually difficult to explain. Usually a kettle appendation is meant to be equipment that is used so that the kettle can work continuously safely. Even this definition is actually still not quite right. Because a kettle, for example, must also be equipped with a filling water pump or another filling device, but this pump cannot be called an appendation, as can a hole in a person.

The Steam Law explains the auxiliary devices of a steam boiler that are all devices to ensure the safe use of a boiler, including filling water pumps, installation and mannequin installation. However, according to the Steam Law, assistive devices which are not attached to the boiler body are not included as kettle appendations.

Water circulator (hydroquineter), advanced heating, reduction valves are not included as auxiliary devices, but are part of the boiler.

The kettle application can be divided into two groups:

☸️The applications related to steam rooms are:

1. Safety valves

2. Main and auxiliary steam valves

3. Manometer

☸️Applications relating to water chambers, are

1. Glass of estimator

2.Fill valve or valve cover closure

3. Spui tap and brein tap.

APPENDATION OF Steam Kettle

A.TINJAUAN GENERAL:

Steam Boilers are equipped with a number of equipment including measuring gases, filling valves, manometers, taps, safety valves, etc. that cause the kettle to work. Such tools are called kettle appendations. A definition of kettle appendation is actually difficult to explain. Usually a kettle appendation is meant to be equipment that is used so that the kettle can work continuously safely. Even this definition is actually still not quite right. Because a kettle, for example, must also be equipped with a filling water pump or another filling device, but this pump cannot be called an appendation, as can a hole in a person.

The Steam Law explains the auxiliary devices of a steam boiler that are all devices to ensure the safe use of a boiler, including filling water pumps, installation and mannequin installation. However, according to the Steam Law, assistive devices which are not attached to the boiler body are not included as kettle appendations.

Water circulator (hydroquineter), advanced heating, reduction valves are not included as auxiliary devices, but are part of the boiler.

The kettle application can be divided into two groups:

☸️The applications related to steam rooms are:

1. Safety valves

2. Main and auxiliary steam valves

3. Manometer

☸️Applications relating to water chambers, are

1. Glass of estimator

2.Fill valve or valve cover closure

3. Spui tap and brein tap.

According to the Steam Law, a kettle must be equipped with the following appendix tools:

✔️ 1 main steam valve and several auxiliary steam valves.

✔️2 safety valves

✔️1 fruit manometer

If the kettle can be taped from the front and back, then at each packing location each is equipped with 1 manometer

✔️2 measuring cups

If the kettle can be taped from the front and back, then in each bag must be installed each 2 measuring cups or in one of the packing places can be placed 1 measuring glass mounted in the middle.

✔️ 2 filling valves or filling valve cabinets.

✔️1 pieces of spui tap or according to their needs.

In addition, for each kettle with a content greater than 6 liters according to the provisions, a brass plate or brors with a size of 80 x 140 mm must be installed.

This stamp plate is attached to the boiler plate with copper Reeling nails, then the nail is stamped by the Office of Work Safety Supervision in such a way that the stamp was half hit on the nail and half hit by the boiler plate.

According to the provisions on the stamp plate data must be included from the relevant kettle (see picture), namely:

1. Name and boiler factory

2. Year of manufacture

3. Working pressure

4. Factory number

5. Register number

By seeing the stamp plate, it means that the boiler has received permission to use it.

B. CONSTRUCTION AND PROVISIONS OF EACH APPENDATION KETEL

Below will be described the construction and working methods of each steam boiler application.

1. Security Valve:

The point

➡️To prevent the pressure inside the boiler not to exceed the working pressure specified in the regulations.

✔️To immediately stop the kettle by releasing steam or water when there is damage to the kettle.

✔️To be able to empty the kettle immediately if the officer wants an immediate inspection.

2. MAIN VALUES AND HELP:

The point:

The main steam valve is used to regulate the delivery of steam to the main engine. Auxiliary Steam Valves are used to regulate the flow of steam to auxiliary planes. Must be installed as close as possible to the kettle and the valve must be able to be opened and closed from the top of the deck.

1.MANOMETER.

The point:

This tool is used to show the excess pressure inside the kettle clearly and precisely.

4. GLASSES INSTALLING.

The point:

To find out where the high water level is inside the kettle.

5. VALVE CHARGING WATER VALVE

The point:

a.To regulate the amount of filling water that enters the kettle.

b.To prevent the boiler water does not come back out of the filling channel when there is a disruption in the filling pump; for example the filling pump is dead.

6. SPUI DROUGHT AND BREIN TIRES

The point:

The Spui tap is used to remove part or all of the kettle.

Partial removal is intended to remove impurities that settle to the bottom of the kettle and to remove them entirely is to empty the kettle if deemed necessary.

The real purpose of SPUI is to remove water and impurities from the kettle by using the steam pressure in the kettle.

APPENDATION OF Steam Kettle A.TINJAUAN GENERAL: Steam Boilers are equipped with a number of equipment including measuring gases, filling valves, manometers, taps, safety valves, etc. that cause the kettle to work. Such tools are called kettle appendations. A definition of kettle appendation is actually difficult to explain. Usually a kettle appendation is meant to be equipment that is used so that the kettle can work continuously safely. Even this definition is actually still not quite right. Because a kettle, for example, must also be equipped with a filling water pump or another filling device, but this pump cannot be called an appendation, as can a hole in a person. The Steam Law explains the auxiliary devices of a steam boiler that are all devices to ensure the safe use of a boiler, including filling water pumps, installation and mannequin installation. However, according to the Steam Law, assistive devices which are not attached to the boiler body are not included as kettle appendations. Water circulator (hydroquineter), advanced heating, reduction valves are not included as auxiliary devices, but are part of the boiler. The kettle application can be divided into two groups: ☸️The applications related to steam rooms are: 1. Safety valves 2. Main and auxiliary steam valves 3. Manometer ☸️Applications relating to water chambers, are 1. Glass of estimator 2.Fill valve or valve cover closure 3. Spui tap and brein tap.